- PowerFlex ® 4 and PowerFlex® 40 AC Drives Technical Data Providing users with powerful motor speed control in a compact, space saving design, the Allen-Bradley PowerFlex 4 and 40 AC drives are the smallest and most cost-effective members of the PowerFlex family of drives. Available in power ratings from 0.2 to 11 kW (0.25 to 15 HP) and in voltage.

- In this manual we refer to the Po werFlex 4 Adjustable Frequency AC Drive as: drive, PowerFlex 4 or PowerFlex 4 Drive. Parameter numbers and names are shown in this format: The following words are used throughout the manual to describe an action: Similar PowerFlex 4 drive sizes are grouped into frame sizes to.

- PowerFlex 4 Adjustable Frequency AC Drive FRN 5.xx This Quick Start guide summarizes the basic steps needed to install, start-up and program the PowerFlex 4 Adjustable Frequency AC Drive. The information provided Does Not replace the User Manual and is intended for qualified drive service personnel only.

- 0 = Keypad 1 = 3-Wire 2 = 2-Wire 3 = 2-Wire Level Sensitive 4 = 2-Wire High Speed 5 = RS485 (DSI) Port 9 = Jog Speed Command Digit 1 0 = Drive Potentiometer 1 = A409 Internal Freq 2 = 0-10V Input/Remote Potentiometer 3 = 4-20mA Input 4 = A410 - A413 Preset Freq x (t201 - t202 Digital Inx Sel must be set to 4) 5 = RS485 (DSI) Port 9 = Jog Freq Reserved Digit 2 Reserved Digit 3.

Our PowerFlex ® 755 AC Drives provide ease of use, application flexibility, and high performance. They include multiple control and hardware options, as well as optional embedded safety features. These drives are well-suited for a wide variety of motor control.

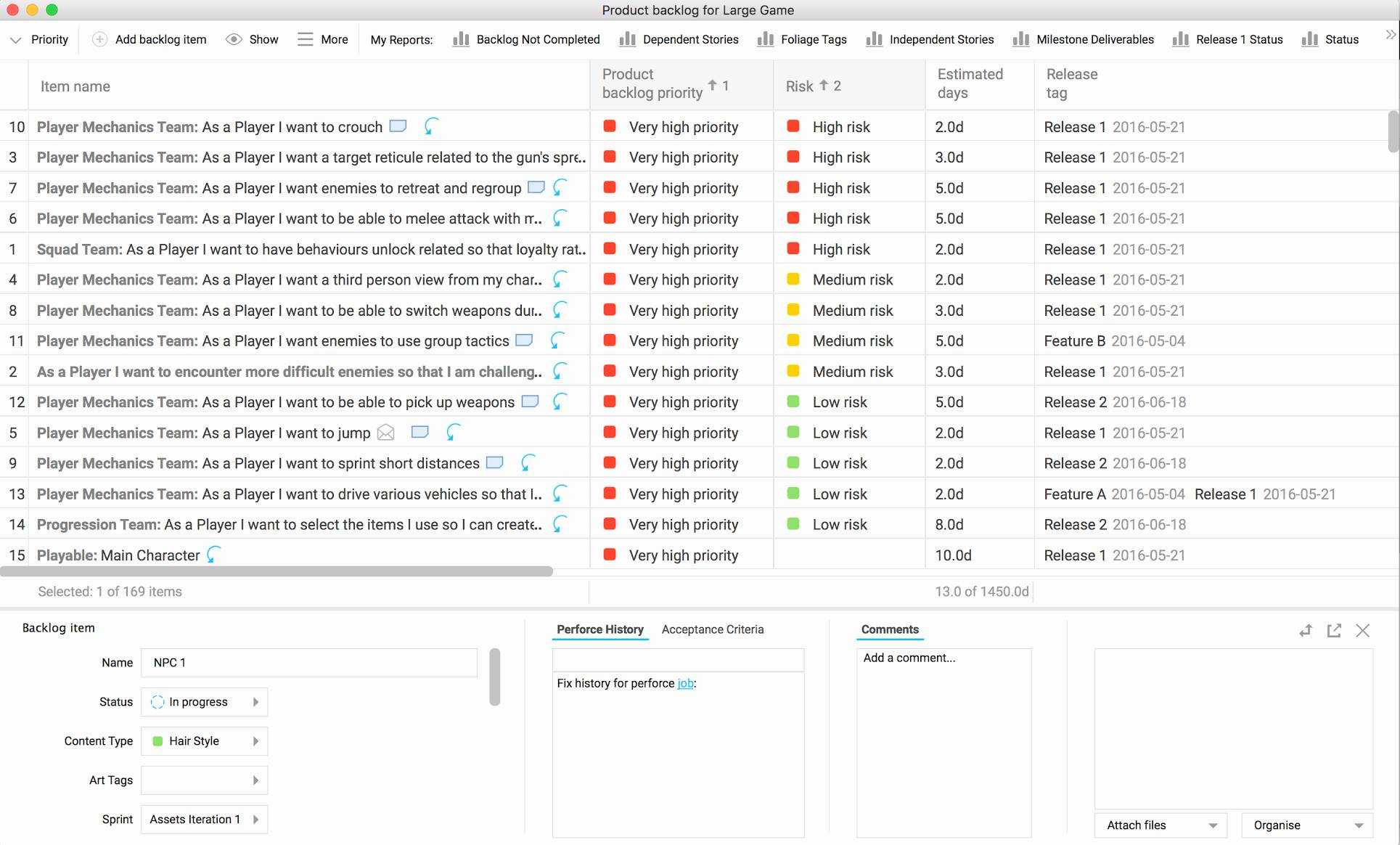

Powerflex 4 Parameter Spreadsheet

– An estimate sent a week provides the client reason to shop about for a better deal, and appears lazy. The rough estimate suggests the phases of product building and the time required for their implementation. Together with this, the estimate that is thorough shows the total amount of danger for each item in the list.

Loan Amortization Agreement Nice Powerflex 4 Parameter Spreadsheet from powerflex 4 parameter spreadsheet , source:olearyforcongress.com

As stated above analysis can be carried out either at the conclusion of the period, or at the start of the financial period. Financial analysis is crucial to comprehend, project company. A single analysis can enable you to realize that what went wrong in the present month or even in the month. For instance if you’re making a stock exchange analysis and need the most recent information of some stock prices at NYSE, you can link your Excel file into a data feed let it take the newest info automatically ( in case you don’t wish to enter them one by one!)

Now all you have to learn is the procedure and the structure. The budget procedure may get very intricate. To get that location you’re going to need to make sure you have submitted. It’s a easy to use application that anyone of your staff members can master in a couple of minutes. Unless you can create your application stick out from the applicants you could find that you aren’t chosen that you would like. The part of your program will be your private statement. Your internet application could be used by individuals from computers that are public.

CATALOGO DE PRECIOS 2007 by FRANKLIN CHAVEZ issuu from powerflex 4 parameter spreadsheet , source:issuu.com

You place all your creative ideas in the shape for fast formatting and may use the file for a template. You might realize that using a file writing kit is fantastic for organizing and creating any sort of document. You’re able to manage and alter documents even when there’s no connectivity. Instead, the time that ought to be spent on each field of work is indicated by the document. A business document writing kit is excellent for assembling all types of Word file. Additional documentation is necessary.

You most likely already gather some of the info you’ll need to construct a personabasic demographic and geographic data. The information may be under requirements, or qualifications or something different. You likely already know all of the information that you want to include, or at least you know the best place to locate it.

ricoh user manual from powerflex 4 parameter spreadsheet , source:ricoh-user-manual.elzplorers.de

Provided that you ask the questions, you’re likely to receive the most acceptable info to decide on a building that has a sublet policy that fulfills your approval. Please do not hesitate to contact me if you’ve got questions. Please do not hesitate to contact me at any given time when you have any questions.

Bill Tracker Spreadsheet from powerflex 4 parameter spreadsheet , source:duboismuseumassociation.org

As soon as you’ve made a statement then all you’ve got to do is store it in a place on your PC. You might incorporate a statement describing. The income statement comprises the operation of the company, that shows the effect of non-operating and operating actions on expenses and the revenues of the organization. So your personal statement will generally be the means to inform you apart. So you must make certain that your statement differs. The announcement in organizations’ balance sheet and yearly report often informs investors about the operation of the enterprise.

Drum Unloader S Drum 200L from powerflex 4 parameter spreadsheet , source:manualzz.com

Have a look at the very best prerequisites and see whether you’ve got another example in a work experience with fewer bullets. It’s possible to find adequate illustration supporting statement online which help you learn to compose a statement of service. Employing an instance of private announcement writing for your policing program is an extremely good method to comprehend exactly what is expected of you.

sanyo ce42fd90 b manual ebook from powerflex 4 parameter spreadsheet , source:sanyo-ce42fd90-b-manual-ebook.zettadata.solutions

The templates in a kit enable you and can supply a jump start on making your manual to you. When you’re trying to lose or maintain your weight, they can be useful. The templates in our section will help alleviate a number of the financial stress which comes with such a purchase. You can put it, if it’s space for an address. Despite a exceptional template , however, you may not have a handle on where to begin. In the event the statement template that is original isn’t derived from external input, SQL injection cannot occur.

Rl Spreadsheet Lovely Sba Financial Statement – Spreadsheet from powerflex 4 parameter spreadsheet , source:divaandmeproductionsinc.com

Thanks for visiting our website. Nowadays we’re delighted to declare that we have discovered an incredibly interesting niche to be discussed. Many individuals searching for specifics of Powerflex 4 Parameter Spreadsheet

and definitely one of these is you, is not it?

gm 5l40 manual ebook from powerflex 4 parameter spreadsheet , source:gm-5l40-manual-ebook.logoutev.de

20 Unique S Corp Partnership Agreement from powerflex 4 parameter spreadsheet , source:hoinghana.com

Powerflex 4 Parameter Spreadsheet – Spreadsheet Collections from powerflex 4 parameter spreadsheet , source:buzzmclaughlinscripts.com

Related posts:

Introduction

Variable Frequency Drives are used within the automation industry to drive induction motors with added precision over a simple contactor. Over the last decade, these devices have become increasingly cheaper. Based on this phenomenon, it’s now recommended to utilize a VFD over a contactor in every application. VFDs are flexible, provide additional control and data in every application.

The PowerFlex 525 series of Variable Frequency Drives from Allen Bradley are an excellent choice & have been an industry standard for several years. Their reliability as well as ease of use, especially within the Rockwell Automation ecosystem, has allowed them to become popular all over the world.

Comissioning a PowerFlex 525 VFD is straightforward. These drives can be easily wired to start and stop from push buttons through direct inputs. However, a much more practical approach is to add the drive to a private network which includes a Programmable Logic Controller. By doing so, the programmer is able to create advanced motion routines in addition to the simple start and stop features. In this tutorial, we’ll take a look at how to integrate a PowerFlex 525 VFD into RSLogix Studio 5000 over EtherNet IP.

PowerFlex 525 Variable Frequency Drive Basic Wiring and Parameters

PowerFlex 525 VFD DataSheet: Click Here

Within the datasheet, the user will find a lot of information about the setup of the drive. This includes wiring diagrams as well as parameters which we will be setting up shortly.

In terms of wiring, the simplest method of controlling the drive without a PLC is through the use of a start and stop push buttons. The diagram below (taken from the manual) illustrates how this can be accomplished. Note that although this method is simple, it’s not the recommended way to use these drives.

Note that there’s a pre-installed jumper between terminals 01 and 11. This jumper needs to be in place while the drive is controlled over EtherNet/IP. If you’re planning on using pushbuttons, the jumper must be removed.

Within the datasheet, you’ll find parameters which may be configured to suit a specific application. These parameters are split into six sections:

- Basic Display

- Basic Program

- Terminal Blocks

- Communications

- Logic

- Advanced Display

Each section has specific parameters for the drive. As the names suggest, parameters within a section will address the setup of electrical parameters, communication with other devices, logical programming and the display of the drive.

Controlling PowerFlex 525 Drives over EtherNet IP

Establishing EtherNet IP connectivity to a PowerFlex 525 drive requires us to set the IP address and the subnet mask. However, the drive may take an IP address setting from Rockwell’s BOOTP Utility or the parameters. Therefore, we must start with the following:

- Set C128 to 1 “Parameters”.

By setting C128 to 1, as the figure above illustrates, we’re telling the drive to look at the parameters for the IP address over BOOTP.

The next step is to give the drive an IP address. This is achieved through the following steps.

- Set C129 to the integer of the first octet.

- Set C130 to the integer of the second octet.

- Set C131 to the integer of the third octet

- Set C132 to the integer of the fourth octet.

By setting those four parameters, the IP of the drive will be as follows: C129.C130.C131.C132. Example: 192.168.1.7

The next step is to give the drive a subnet mask. This is achieved through the following steps.

- Set C133 to the integer of the first octet.

- Set C134 to the integer of the second octet.

- Set C135 to the integer of the third octet

- Set C136 to the integer of the fourth octet.

By setting those four parameters, the subnet mask of the drive will be as follows: C133.C134.C135.C136. Example: 255.255.255.0

Lastly, we need to re-boot the drive for the address to take:

- Set P053 to 4 “Module Reset”

By setting this parameter to 4, the module is reset without affecting the memory of the drive. This is a required step in order for the drive to set the parameters we’ve given it in the previous steps.

Wiring Start Stop Push Buttons into CompactLogix Allen Bradley PLC

Now that the PowerFlex 525 VFD is controlled through EtherNet/IP, we need to add external controls to our PLC. We will be adding a start and stop push buttons to control our drive through some basic ladder logic. The L24ER-QB1B PLC is equipped with Inputs and Outputs directly on the main hardware. Since we’re only using push buttons for this example, we only need to worry about the inputs.

The PLC inputs may be configured as sourcing or sinking. This concept is often missunderstood by engineers and technicians. However, the datasheet of the PLC provides a comprehensive diagram. Furthermore, a simple pushbutton may be wired to be a pseudo PNP or NPN device. The reason we say “pseudo” is that a push button doesn’t contain a transistor and is simply driving the voltage High or Low. A PNP or NPN designation is typically used in case of a sensor which uses a transistor.

The image obove displays both configurations with the sinking one highlighted. Furthermore, the two inputs, 00 and 01, are shown as well. These inputs are used for the start and stop button.

The image above is the actual PLC with the common landed on the 0VD terminal and the two buttons landed on the inputs 00 and 01.

On the button side, the Start button is wired as normally open while the Stop button is normally closed. This is the typical wiring scheme based on a hardware circuit configuration. This can be achieved by selecting an appropriate button type or by selecting the ones that have either option available. Note that through software, you may program the buttons to work in any configuration; our typical preference is to keep all buttons normally open.

Once the PLC is powered up, the inputs are tested. The normally closed input should be “High” while the normally open one should be “Low”. Once either button is pressed, the input should transition to the opposite state.

Adding the PowerFlex 525 VFD to RSLogix Studio 5000

We’ve placed the drive onto the same physical network as the PLC and gave it an IP address which allows it to communicate to the controller. We now need to configure the drive through the software in order to program the control. This is achieved through RSLogix or Studio 5000 depending on the flavor of the PLC used in the control system. However, the steps should be the same with minor differences due to firmware revisions.

Powerflex 40 Fault Codes

Step 1 – Adding the drive to the IO tree

By right-clicking the EtherNet node of the PLC, it’s possible to “Add a New Module”. Once the window is opened, find the device you wish to add by searching in the specified area or by scrolling down through the list. Note that you may need to install the drivers on older PLCs. They can be found through the Rockwell Automation download center and installed on the local machine which has RSLogix or Studio 5000.

Step 2 – Configuring Parameters

Once the drive is added & the hardware is properly connected to the controller, it’s possible to configure the internalt drive parameters through RSLogix Studio 5000. Note that if the IP, subnet mask or the physical network aren’t correct, the user won’t be able to access the parameters at all.

Configuring the parameters is done based on the datasheet. For a simple control scheme it’s enough to set the drive to be controlled over EtherNet/IP and set the correct Voltage levels based on the motor. It’s recommended to verify the physical setup of your specific control system before proceeding with testing a live motor.

Note that the same parameters are displayed in this prompt as the ones we accessed through the drive at the start of the tutorial. You may change them through the drive or through the programming interface. For obvious reasons, it’s much simpler to change them through RSLogix Studio 5000.

Programming Start Stop Ladder Logic in RSLogix Studio 5000

We’ve shown an example of programming a simple start and stop routine in one of earlier videos, but in this case, we’re using buttons which aren’t both normally open and the drive has tags which are generated by the software.

Here’s what the tag structure of the PowerFlex 525 Drive looks like when the drive is added into the program:

Powerflex 4 Parameters Pdf

Each one of these tags can be used as an Input/Output in order to control the drive in a certain way. However, the most utilized and needed tags are Start, Stop, ClearFaults, Forward, Reverse, FreqCommand and the output tags for diagnostics. Note that it may be confusing by the nomenclature, but the tags labeled as O are PLC outputs, drive inputs. The opposite is true of the tags labeled as I. In other words, they’re inputs and outputs depending on what the reference is taken.

The logic you choose to write is entierly up to you, but at the very least, you’d want to start and stop the motor. Beyond that, you can implement speed control and forward/reverse if needed. Lastly, you’d want to implement a way to incoporate the input tags into your routine to detect faulted conditions. You may choose to add advanced routines which would monitor the acceleration and deceleration to fine tune what the drive is doing.

Powerflex 4 Parameters

Here’s the logic to get the motor to start and stop based on the two buttons we’ve added earlier in the tutorial:

Conclusion

Selecting a Variable Frequency Drive over a contactor should be a no-brainer in most current applications. In the Allen Bradley selection, the most commonly used VFD is a PowerFlex 525 for small motors. Similar part numbers are available for larger drives. This drive is easily networked onto the plant infrastructure and communicates to the PLC over EtherNet/IP.

By building a small motor starter circuit in this tutorial, we’ve demonstrated the ease at which one can add a PowerFlex 525 VFD to the RSLogix Studio 5000 PLC Program running on an L24ER-QB1B processor. The VFD is programmed to start and stop based on the presses of the two buttons wired into the local inputs of the same PLC.